China Candy Depositing Machine

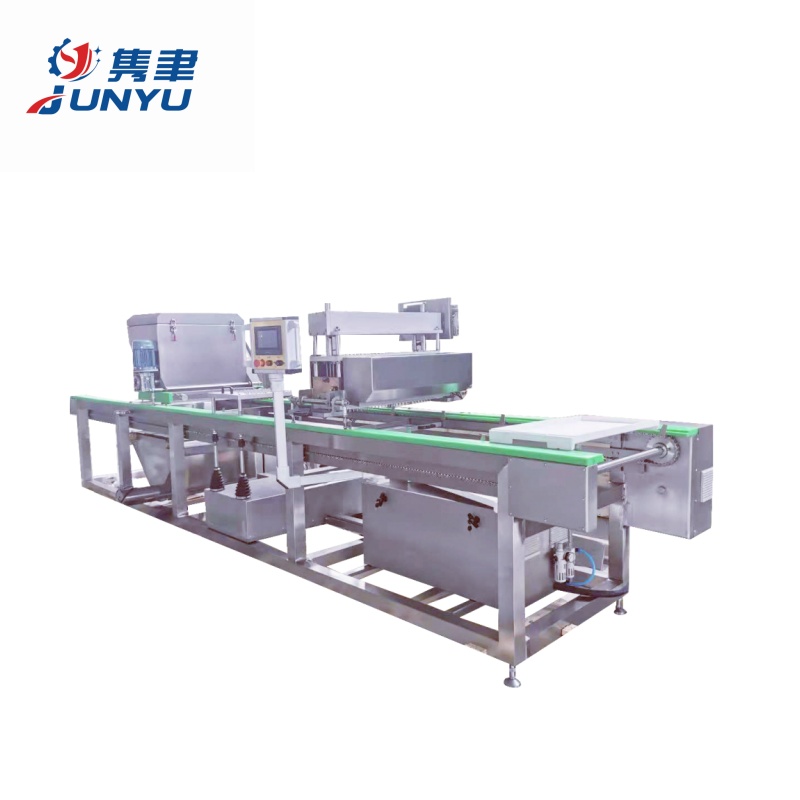

JY-150 Candy Depositing Machine

Mid-capacity depositor optimized for gummy and soft-centre candies.

The JY-150 is a versatile depositor for gummy and soft candy formulations, providing precise dosing and stable production for growing manufacturers.

Key Specifications

- Capacity: 150 kg/h

- Output: 40,000 pieces / h

- Power: 30 kW

- Role: Mid-size depositor for gummy/soft candy

- Ideal for: Medium-scale confectionery brands

H-300 Hard Candy Depositing Machine

Medium-scale hard-candy depositor for clear, boiled and molded sweets.

The H-300 supports consistent hard-candy dosing and finish, suitable for flavored boiled candies and molded confections with stable throughput.

Key Specifications

- Capacity: 300 kg/h

- Output: 48,000 pieces / h

- Power: 35 kW

- Role: Hard-candy depositor for mid-volume runs

- Ideal for: Traditional candy makers & private-label production

JYS-80 Semi-Automatic Starch-Mogul Depositor

Semi-auto starch-mogul solution for shaped candies and depositor-integrated mogul lines.

JYS-80 is a semi-automatic mogul depositor combining flexible tray sizes with repeatable depositing speed — suited for shaped jelly, marshmallow and novelty candies using starch molding.

Key Specifications

- Tray size: 40 × 80 cm

- Candy quantity: ~528–720 pcs / stork (per tray)

- Depositing speed: 15–20 times / min

- Role: Semi-automatic starch-mogul depositor

- Ideal for: Small-to-medium mogul production, R&D and pilot lines

About Junyu

Shanghai Junyu Food Machine Co., Ltd., founded in 1987, supplies turnkey confectionery lines and specialized depositing machines to customers worldwide.

Based in Shanghai’s Fengxian Industrial Zone, Junyu combines 30+ years of manufacturing experience with advanced R&D and CNC processing to deliver scalable, food-grade candy depositing solutions. :contentReference[oaicite:2]{index=2}

Why Choose Junyu for Depositing Machines

Junyu offers proven depositors, custom tooling and full-line services — enabling reliable candy depositing across gummy, hard candy, starch-mogul and lollipop lines.

Proven Production

Decades of confectionery expertise produce dependable depositors and predictable uptime.

Multi-Format Support

Depositors accommodate gummy, hard candy, starch-mogul and stick-insert formats with tailored tooling.

Turnkey Projects

From process design to installation and training, Junyu delivers end-to-end line commissioning.

Global After-Sales

Export experience ensures spare parts, service and technical guidance for international customers.

Food-Grade Engineering

Hygienic designs and high-precision manufacturing reduce contamination risk and downtime.

Scalable Options

Models scale from pilot and craft setups to high-capacity industrial lines.

China Advantages for Depositing Equipment

Cost-Effective Supply

Competitive manufacturing lowers equipment cost while preserving engineering quality.

Automation & Precision

Modern controls improve deposit accuracy and reduce product variation and waste.

Customization

Tooling, stick systems and mold design are customized for brand-specific products.

Export Experience

Established logistics and after-sales support simplify international deployment.

Top Chinese Manufacturers of Depositing Machines

China hosts experienced confectionery-equipment makers. Junyu is a leading supplier offering turnkey depositing machines, custom tooling and global technical services to ensure smooth production ramp-up. :contentReference[oaicite:3]{index=3}

Customization for Depositing Lines

Junyu customizes depositor tooling, dosing profiles, stick insertion and integration with packaging to meet product and packaging requirements.

- Tooling & Dies: CNC-made molds for unique shapes and textures.

- Process R&D: Recipe tuning for texture, clarity and shelf-life.

- Hygienic Design: Materials and finishes that meet modern food-safety needs.

- Turnkey Delivery: Layout planning, installation and operator training included.