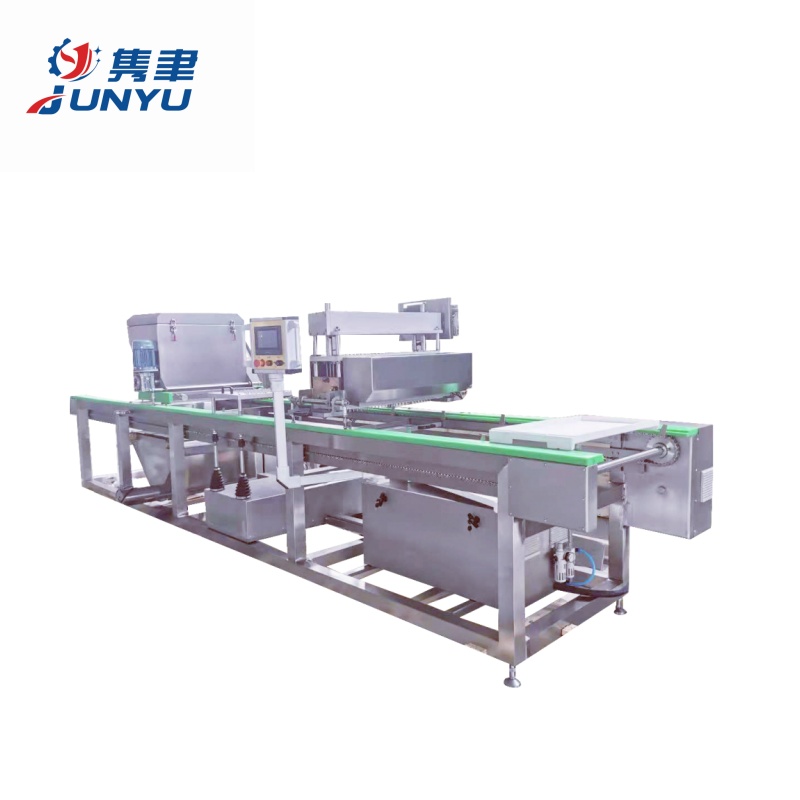

China Starch Mogul Production Line

Junyu-S462 Full Automatic Starch Mogul Line

High-efficiency fully automatic mogul line for continuous production.

The Junyu-S462 is a full automatic starch mogul line engineered for steady, high-quality output with precise tray handling and robust drying control. Designed for manufacturers seeking consistent production rates with minimal manual intervention, the S462 is suitable for shaped candies and starch-molded gummies that require reliable tray throughput.

Key specifications

- Speed: 35 trays/min

- Tray dimensions: 760–840 × 360–440 mm

- Typical use: Continuous full-automatic production lines

Junyu-S660 Full Automatic Starch Mogul Line

High-efficiency full automatic line with alternative tray orientation.

The Junyu-S660 offers the same 35 trays per minute throughput in an alternative tray layout, providing flexibility for factories that prefer the rotated tray orientation. It is engineered for dependable tray handling, uniform drying and smooth demoulding to preserve product shape and appearance at scale.

Key specifications

- Speed: 35 trays/min

- Tray dimensions: 360–440 × 760–840 mm

- Typical use: Continuous full-automatic production lines with rotated tray format

JYS Series Semi-Automatic Starch Mogul Lines (JYS-40 / JYS-60 / JYS-80)

Semi-automatic mogul solutions for flexible production and lower CAPEX.

The JYS series provides semi-automatic starch mogul capability for manufacturers balancing investment and flexibility. All JYS models operate at a depositing speed of 15–20 times per minute, making them suitable for niche production, private-label work and pilot scaling projects.

Key specifications

- Models: JYS-40 / JYS-60 / JYS-80

- Tray sizes: JYS-40 = 40×40 cm; JYS-60 = 40×60 cm; JYS-80 = 40×80 cm

- Candy quantity (approx.): JYS-40: 64–180 pcs/stork; JYS-60: 200–300 pcs/stork; JYS-80: 528–720 pcs/stork

- Depositing speed: 15–20 times/min

- Typical use: Semi-automatic production, private label and pilot scaling

About Junyu

Shanghai Junyu Food Machine Co., Ltd. is a specialist in confectionery equipment, offering design and turnkey delivery for starch mogul lines. Junyu combines in-house machining, process R&D and full-line testing to supply production-ready systems for global customers.

Junyu’s facilities support pilot trials, FAT validation and on-site commissioning to ensure predictable time-to-production.

Why Choose Junyu for Starch Mogul Lines

Junyu delivers integrated starch mogul systems that combine accurate depositing, hygienic starch handling, zoned drying and controlled demoulding to maximize yield and minimize product defects, backed by commissioning and after-sales support.

Full-line expertise

Experience in mogul deposition, starch handling and drying technologies.

Hygienic design

Food-grade contact surfaces, dust control and easy-clean access.

Process controls

PLC/HMI recipe management, multi-zone drying control and demould timing.

Turnkey delivery

From layout design and FAT to logistics, commissioning and training.

Spare parts & service

Local spare kits, preventive maintenance and remote diagnostics.

Scalable options

Modular designs that grow from pilot to full industrial capacity.

China Advantages for Mogul Equipment

Competitive cost

Cost-effective manufacturing with established local supply chains.

Engineering depth

In-house machining cells and long experience in confectionery processes.

Turnkey vendors

One-source suppliers for depositing, starch handling and packaging.

Export experience

Packaging, documentation and logistics for international shipments.

Top Chinese Manufacturers of Mogul Equipment

China’s mogul-equipment manufacturers supply integrated systems covering depositor modules, starch-bed handling, reclaim systems, zoned drying tunnels, demoulding stations and downstream conveying and packing. Leading suppliers demonstrate this capability with FAT records, on-site references, material traceability and structured commissioning plans.

Buyers should evaluate vendors on starch-dust control, reclaim efficiency, drying uniformity and demould yield to ensure efficient, hygienic operation and predictable ramp-up to commercial output.

Customization & Turnkey Services

Junyu provides tailored mogul solutions that start with a site and utilities audit, recipe review and process mapping. Engineering deliverables include 2D/3D layouts, PLC/HMI integration and bespoke tooling for shaped or embossed products. FAT is conducted to validate throughput, demould yield and finished appearance before shipment. On-site commissioning covers installation, electrical integration, trial runs and operator training. Lifecycle services include spare parts kits, preventive-maintenance schedules and optional telemetry for OEE tracking and recipe control.