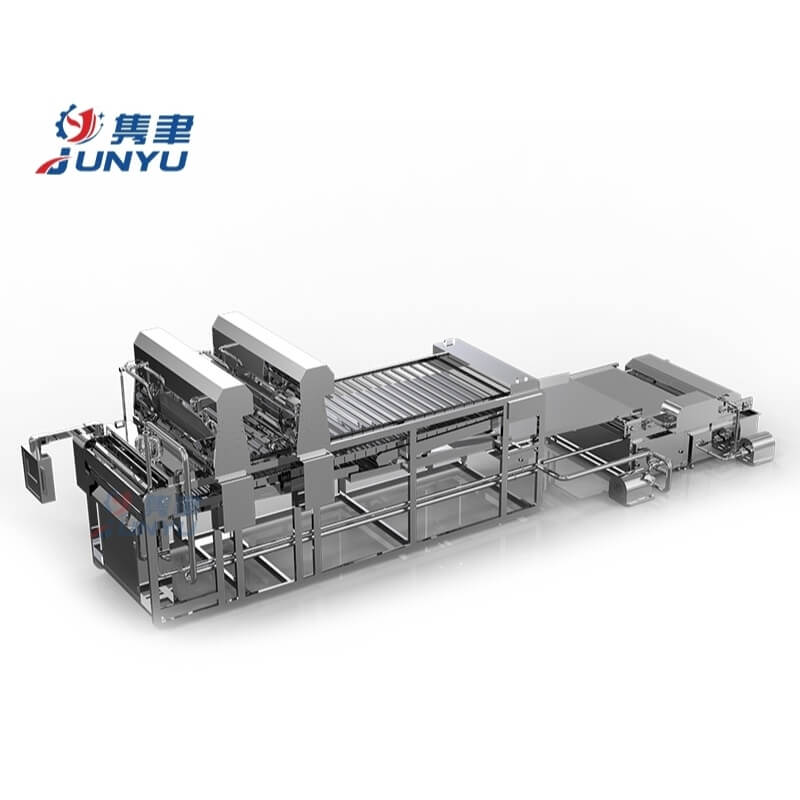

Full Automatic Popping Boba Production Line

Description

Reviews

The popping boba can be used in juice,milk tea, ice cream, cake decoration, egg tart filling, caviar and daily chemical products such as cosmetics, shower gel, etc.

Note: there are three liquids in this system, they are juice(the main ingredients are water, glucose syrup, calcium lactate, white granulated sugar, Guar gum, xanthan gum, concentrated juice, Citric acid, and etc.. It is used to be the inner of popping boba), the Sodium alginate liquid(or you can call it solidification liquid, the main ingredients are water and Sodium alginate, it is used to forming the outer of popping boba), the Protection liquid(the main ingredients are water, fructose, and etc. It used to protect the popping boba in the packing box)

Product Specifications

Made mainly of high - grade stainless steel , it adheres strictly to food hygiene standards. The production process is fully automated, from the mixing of the outer gel (derived from seaweed extract) and the filling of flavorful juices (such as mango, strawberry, or lychee) to the curing and cleaning stages. This not only reduces labor costs but also ensures a high - quality output with minimal waste. Output capacities can range from 20 to 500 kgs/h, meeting the demands of small - scale producers and large - scale food manufacturers alike.

| Model | Particle Number (N/H) | Electric Power(KW/V) | Length(M) |

| JY-50 | 40,000 | 5 | 5 |

| JY-100 | 90,000 | 20 | 11 |

| JY-300 | 300,000 | 25 | 11 |

| JY-600 | 600,000 | 30 | 11 |

Advantage

- All machines made of SUS304, Electric apply for UL certificate.

- Syrup storage using vacuum treatment to reduce air bubbles.

- Compact machine structure, high performance.

- All parts and machines handle Germany's standard sandblasting surface coating.

- With the function of sanitary liquid recycle system.

- Boba size can adjustable.

- Three layers of ramp transport to make the boba more round.

- All machine parts fully welding and washable.

The Process of Popping Boba Production Line

Core/filling syrup cooker & shell/sanitary liquid cooker & storage

After mixing the filling material in proportion, heat and boil it, at the same time heat and boil the sanitary liquid in another cooker.

And then transfer them into the separated storage tank for cooling and storage.

Also can vacuum the syrup for reduce the air bubble.

Bubble juice filling ball depositing machine

The shell/sanitary liquid will be transferred to the molding tank through the transfer pump.

Core material through storage tank is transferred to the depositing machine hopper, PLC touch screen control core material depositing amount, dropping in the forming liquid tank, produce calcification reaction.

After the surface of the core material is crusted then forming.

Popping Boba shell/sanitary liquid Separate

As the boba flow along the slope and become more and more round, and after passing through three layers of flow, then they separate from the sanitary liquid.

Film/sanitary liquid recycle

The sanitary liquid fall into collect tank and then recovered and then pumped back into the boba forming tank.the boba will transfer in to the collect tank.