Over 30 Years Production Experience

Provide You with Gummy Candy Production Line Solutions

Trustworthy China Candy Machine Manufacturer>

The Most Popular Gummy Candy Production Line Series

Medium Scale Gummy Production Line

JY-80

Medium Scale Gummy Production Line

JY-150

Large and Ultra Large Gummy Candy Production Line Series

Large Scale Gummy Production Line

JY-300

Large Scale Gummy Production Line

JY-600

Ultra Large Scale Gummy Production Line

JY-1500

Applications

Sour Belt Candy Machine

Related Products

Candy / Gummy Kitchen CIP Cleaning System

Steam-Humidifying & Sugar-Sanding Machine

Automatic Weighing & CFA Adding Station

Raising Film Continuous Cooker

Specification Sheet for a Standard Gummy Production Line

| Model | Capicity(kg/h) | Casting Particles(hr) | Power(kw) |

| JY-50 | 50 | 15,000 | 20 |

| JY-80 | 80 | 25,000 | 20 |

| JY-150 | 150 | 40,000 | 30 |

| JY-300 | 300 | 80,000 | 35 |

| JY-450 | 450 | 120,000 | 40 |

| JY-600 | 600 | 240,000 | 45 |

| JY-1500 | 1500 | 800,000 | 50 |

| Stage | Parameter | Range |

| Preparation | Batch Size | 100 kg - 1000 kg |

| Raw Material Consumption | Gelatin, flavorings, etc. | |

| Mixing Time | 15 min - 1 hour | |

| Cooking and Conditioning | Cooking Temperature | 80°C - 120°C |

| Cooking Time | 2 hours - 4 hours | |

| Cooling Time | 1 hour - 3 hours | |

| Forming and Shaping | Extrusion Rate | 10 kg/h - 100 kg/h |

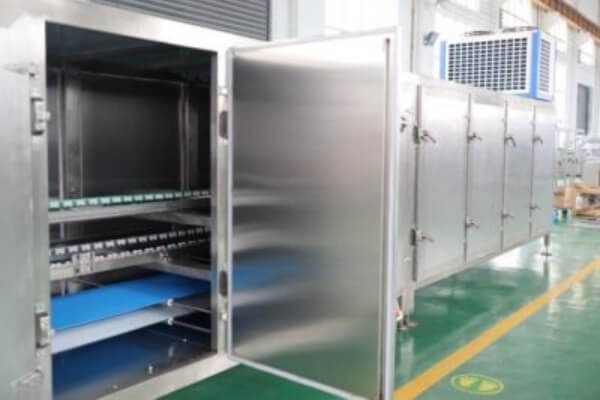

| Drying | Drying Time | 4 hours - 10 hours |

| Drying Temperature | 50°C - 70°C | |

| Packaging | Packaging Speed | 20 packs/min - 100 packs/min |

| Output Rate | Output Rate | 200 kg/h - 1000 kg/h |

| Energy Consumption | Energy Consumption | 50 kW - 150 kW |

| Safety Measures | Emergency Stop Buttons | Yes |

| Guarding | Yes | |

| Metal Detection | Yes | |

| Maintenance | Cleaning Frequency | Daily, after each batch |

| Lubrication Points | Every 40 - 80 hours |

Advantages of Junyu Gummy Machine

Junyu gummy candy production line is the ideal choice to meet the soft candy production needs. Our continuous cooking technologies bring exceptional levels of reliability, efficiency, and low production costs Compared to the ordinary kitchen.

Partner with us to produce unique, high-quality confectionery and nutraceuticals and achieve a high, long-term return on your investment.

Gummy Molds

About Junyu

Top Gummy Candy Making Machine Manufacturer in China

Shanghai Junyu Food Machine Co., Ltd., founded in 1987, is a leading innovator in confectionery machinery, rooted in over three decades of expertise that began with our founder’s pioneering candy machines in the early 1980s.

Based in Shanghai Fengxian Industrial Zone, we design and manufacture world-class candy production lines, delivering tailored solutions to clients in over 100 countries. We are the ideal partner for food companies, raw material suppliers and agents.

Why Choose Us

Types of Gummies We Produce

FAQs

Gummy Candy Production Line Related Resources

Choose the Best China Candy Machine Production Equipment

Junyu is a company dedicated to creating machines that are customized case by case and every gummy machine created is tailor-made to your specific needs.

Why Choose Gummy Candy Production Line?

Choosing our Gummy Candy Production Line ensures you benefit from a fully automated, turnkey solution engineered for high efficiency and consistent quality. Featuring precision-controlled cooking, molding, and cooling units, this production line delivers uniform gummy shapes and textures at up to 500 kg/h capacity, reducing labor costs and minimizing waste. Our equipment is built with food-grade stainless steel, meets CE and ISO standards, and offers modular scalability so you can customize batch sizes and finishes to match market trends. Backed by 24/7 technical support, professional installation, and hands‑on operator training, our gummy candy machinery helps you launch new flavors faster, maintain stringent hygiene standards, and maximize ROI — making it the ideal choice for confectionery manufacturers aiming to stand out in a competitive marketplace.