Over 30 Years Production Experience

Provide You with Hard Candy Production Line Solutions

Trustworthy China Candy Machine Manufacturer

Most Popular Hard Candy Production Line Series

Medium Scale Hard Candy Production Line

H-300

Medium Scale Hard Candy Production Line

H-450

Large Scale Hard Candy Production Line

H-600

Large Scale Hard Candy Production Line

H-1500

Related Products

Candy / Gummy Kitchen CIP Cleaning System

Steam-Humidifying & Sugar-Sanding Machine

Automatic Weighing & CFA Adding Station

Raising Film Continuous Cooker

Specification Sheet for a Standard Hard Candy Production Line

| Model | Capicity(kg/h) | Casting Particles(hr) | Power(kw) |

| H-50 | 50 | 15,000 | 20 |

| H-80 | 80 | 25,000 | 20 |

| H-150 | 150 | 40,000 | 30 |

| H-300 | 300 | 80,000 | 35 |

| H-450 | 450 | 120,000 | 40 |

| H-600 | 600 | 240,000 | 45 |

| H-1500 | 1500 | 800,000 | 50 |

| Stage | Parameter | Range |

| Raw Material Handling | Raw Materials | Sugar, glucose syrup, flavorings, colors |

| Material Compatibility | Various types of sugar and ingredients | |

| Cooking and Mixing | Cooking Temperature | 150°C - 170°C |

| Mixing Time | 15 min - 30 min | |

| Molding and Forming | Molding Shape | Round, heart-shaped, etc. |

| Molding Temperature | 50°C - 60°C | |

| Insertion of Sticks | Stick Size | 100 mm - 150 mm |

| Insertion Speed | 50 sticks/min - 100 sticks/min | |

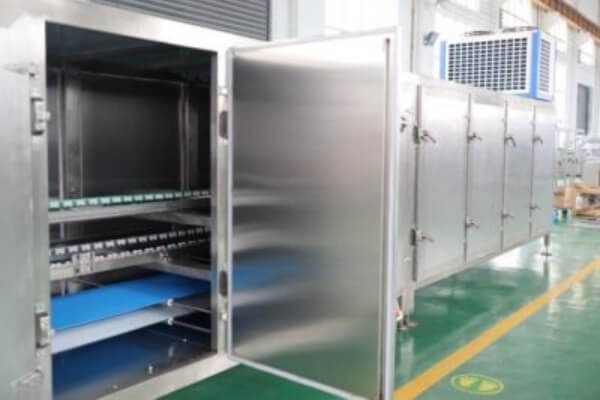

| Cooling and Solidification | Cooling Tunnel Length | 10 m - 20 m |

| Cooling Temperature | 20°C - 25°C | |

| Shaping and Cutting | Cutting Shape | Round, star-shaped, etc. |

| Cutting Speed | 100 cuts/min - 200 cuts/min | |

| Sugar Coating | Sugar Layer Thickness | 1 mm - 3 mm |

| Coating Drum Speed | 20 RPM - 40 RPM | |

| Flavor and Color Application | Application Rate | Adjust based on specifications |

| Inspection and QC | Vision Inspection System | Detecting defects |

| Reject System | Automatically remove faulty lollipops | |

| Packaging | Packaging Type | Wrappers, blister packs, etc. |

| Packaging Speed | 30 packs/min - 60 packs/min | |

| Energy Consumption | Energy Consumption | 50 kW - 100 kW |

| Safety Measures | Emergency Stop Buttons | Yes |

| Guarding | Yes | |

| Maintenance Schedule | Cleaning Frequency | Daily, after each batch |

| Lubrication Points | Every 40 - 80 hours |

Advantages of Junyu Hard Candy Machine

Junyu Hard Candy Machines offer the highest quality production lines at the most competitive prices to produce a wide variety of hard candies. Whether you need single, double, triple or quad colors, you can easily make multi-color, multi-ingredient candies.

Work with us to produce unique, high-quality candies and nutritional supplements and get a high long-term return on your investment.

About Junyu

Top Hard Candy Making Machine Manufacturer in China

Shanghai Junyu Food Machine Co., Ltd., founded in 1987, is a leading innovator in confectionery machinery, rooted in over three decades of expertise that began with our founder’s pioneering candy machines in the early 1980s.

Based in Shanghai Fengxian Industrial Zone, we design and manufacture world-class candy production lines, delivering tailored solutions to clients in over 100 countries. We are the ideal partner for food companies, raw material suppliers and agents.

Why Choose Us

Types of Hard Candies We Produce

FAQs

Choose the Best China Candy Machine Production Equipment

Junyu is a company dedicated to creating machines that are customized case by case and every gummy machine created is tailor-made to your specific needs.

Choose the Best China Candy Machine Production Equipment

What is a hard candy production line?

A hard candy production line is a manufacturing process that produces hard candy at an industrial scale. This process involves several stages, including mixing ingredients, cooking, forming, cooling, and packaging. The primary function of a hard candy production line is to produce consistent and high-quality candy products in large quantities, which is essential in the candy-making industry.

Understanding the Concept of a Hard Candy Production Line

A hard candy production line comprises several main components, including mixing machines, cooking kettles, candy forming machines, cooling conveyors, and packaging machines. The process starts with mixing ingredients in a mixing machine, which then pours the mixture into a cooking kettle to be heated. The cooked candy mixture is then deposited into a forming machine that shapes the candy into its desired form. The formed candy is then transported on a conveyor belt that cools it down to its final hardness. Finally, the candy is packaged in a packaging machine and is ready for distribution.

The Role of Machinery in a Hard Candy Production Line

Mixing machines blend the ingredients uniformly, and the cooking kettles melt and heat the ingredients to the right temperature. Candy forming machines shape the candy, and cooling conveyors accelerate the cooling process by distributing the heat uniformly. Packaging machines are used to weigh, wrap, and label the candy, ready for distribution.

Benefits of Using a Candy Production Line

Using a hard candy production line offers numerous benefits. First, it increases efficiency by automating many of the manual tasks involved in candy making. This results in faster processing times, reduced labor costs, and increased production capacity. Second, using a production line ensures that the candy product is consistent in taste, texture, and appearance, which is important to maintain customer loyalty and satisfaction. Finally, using a production line is more hygienic, minimizing contamination risks and ensuring that the candy products are safe for consumption.

Choosing the Right Candy Production Line Manufacturer

When choosing a candy production line manufacturer, several factors must be considered. The manufacturer should specialize in candy production lines and have a good reputation for producing high-quality equipment. The manufacturer should offer a range of options to suit different candy production needs and be able to provide after-sales support, including maintenance and technical assistance.

How to Contact a Candy Production Line Supplier

There are several ways to contact a candy production line supplier. One way is to search for candy production line manufacturers online and visit their websites to explore their offerings and services. Recommended Supplier: From Junyu, one of the leading manufacturers in China. Another way is to attend trade shows related to the candy-making industry to meet with manufacturers and discuss the available options for candy production equipment. Finally, contacting industry associations and trade organizations can also provide valuable contacts and information on reliable suppliers.

How does a hard candy production line work?

A hard candy production line involves processes that transform raw ingredients into finished products ready for packaging and shipping. This manufacturing process starts with choosing high-quality raw materials and mixing them with water in a large container. The mixture is then heated to a controlled temperature, adding the desired flavor and color. The temperature increases, and the mixture is poured onto a cooling table. The mixture is then kneaded and cut into smaller chunks before moving to the depositing stage.

The Role of Depositing Machines in Hard Candy Production

Depositing machines play a critical role in the production of hard candy. These machines deposit the candy mixture into molds, compressing and shaping the candy into the desired sizes and shapes while leaving it with a smooth finish. These machines use advanced technology to provide uniformity in size, shape, and flavor. There are different types of depositing machines, including rotary, chain, and rope-style machines, and each offers unique benefits, such as precision and consistency in shaping the hard candy.

Step-by-Step Guide to Operating a Hard Candy Making Machine

Operating a hard candy making machine requires precision and care. First, ensure the device is clean, and prepare the candy mixture as needed. Next, feed the mix into the hopper, which is then heated to the desired temperature. The mixture is then deposited into molds by the machine, and once the candies have finished shaping, they are cooled before being released from the molds. Finally, the finished candies are packaged and labeled for distribution.

Exploring Lollipop Production on a Candy Production Line

Lollipops are a type of hard candy that is commonly produced on candy production lines. Lollipop production starts with mixing raw ingredients, and then the mixture is deposited into lollipop molds using a specialized lollipop depositing machine. Once the lollipops have taken shape, they are cooled and wrapped before being packaged.

The Process of Making Jelly Candy on a Production Line

Jelly candy is another popular type of candy produced on candy production lines. Making jelly candy begins by heating sugar, corn syrup, and water to a controlled temperature. Once the mixture has reached the desired temperature, gelatin and flavorings are added and mixed in. The resulting mixture is then deposited into molds using a suitable machine. Once the jelly candies have taken shape, they are cooled and coated with sugar before being packaged.

What are the key features of a hard candy production line?

A hard candy production line comprises a series of machines that work together to create a uniform, high-quality hard candies. These machines include a cooker, batch roller, rope sizer, cooling tunnel, and packaging machines. The oven heats and mixes the ingredients to form a syrup, which is then transferred to the batch roller, cooled, and stretched into a long rope shape. The rope is then passed through the rope sizer, which determines the final size of the candy. The candy is cooled in a cooling tunnel and packaged by the packaging machines.

Understanding the Importance of a Candy Production Line Manufacturer

Choosing the right candy production line manufacturer is critical to the success of any candy business. A good manufacturer will provide state-of-the-art machinery specifically designed for candy production. They will also be able to offer expert advice on the production process and help with troubleshooting. A reputable manufacturer will also provide training and support to ensure operators understand how to operate and maintain the machinery properly.

The Significance of a Hard Candy Depositing Production Line

A hard candy depositing production line is an efficient and accurate way to produce hard candies. Unlike traditional methods, where candy is pulled and stretched mechanically, depositing involves dispensing the candy syrup directly into pre-formed molds. This allows for greater precision and control over the final shape and size of the candy. Additionally, depositing production lines is more cost-effective and requires less labor than traditional hard candy production methods.

Exploring the Role of Confectionery in Candy Manufacturing

Confectionery is an essential component in candy manufacturing. It provides the flavor, color, and texture of the finished product. There are many different types of confectionery, such as natural and artificial flavorings, colors, acids, and texturizers, that are incorporated into the syrup during the cooking stage. Different confectionery combinations can create various flavors, colors, and textures, which appeal to other consumer preferences.

The Benefits of Using a Gummy Candy Production Line

A gummy candy production line is a specialized machine used to produce gummy candies. Gummy candies are made from a mixture of gelatin, sugar, and other ingredients, which are heated and mixed to form a uniform syrup. The syrup is then dispensed into molds and cooled to form the final gummy candy. Using a gummy candy production line offers several benefits, including increased efficiency, accuracy, and product consistency. It also allows for creating customized shapes and flavors, which can be tailored to meet the needs of specific target markets.

Factors to Consider When Selecting a Candy Machinery Supplier

When choosing a supplier, there are several factors to consider, such as their experience and reputation in the industry, the quality and performance of their machines, their customer service and support, and their pricing and warranty options. It's essential to do thorough research and compare multiple suppliers to ensure you make an informed decision that best meets your business needs and goals.

Exploring the Features of High-Quality Candy Making Machinery

High-quality candy-making machinery can help optimize your production processes, increase efficiency, and improve the quality and consistency of your candy products. The best machines usually have advanced automation and control systems, high accuracy sensors and meters, and durable and easy-to-clean components. The devices should also allow for flexibility in recipe formulation and customization and quick and easy adjustments of production parameters. Additionally, the machines should meet industry standards and regulations and offer reliable safety features to ensure a safe working environment for your employees.

Understanding the Role of a Machine Manufacturer in the Production Process

A competent and experienced machine manufacturer can play a critical role in the candy production. They are responsible for designing, developing, and maintaining candy-making equipment that meets industry standards and regulations and can optimize production processes. Manufacturers with in-depth knowledge and understanding of candy manufacturing can also provide technical support and training, help troubleshoot and repair, and continually improve their equipment to keep up with industry trends and demands. Choosing a reputable and innovative manufacturer can help ensure long-term success and competitiveness in the candy industry.

Exploring the Importance of Packaging and Packing Machines

Packaging is a crucial aspect of the candy manufacturing process. Proper packaging protects the product from damage, contamination, and spoilage and enhances the product's shelf appeal and brand recognition. Choosing the right packaging materials and machines can significantly impact your production processes' packaging quality and efficiency. High-quality packing machines should provide precise and consistent filling, sealing, and labeling capabilities, as well as allow for customization and flexibility to accommodate varying package sizes and shapes. Additionally, the machines should meet hygiene and safety standards, be durable and easy to clean, and offer a cost-effective solution to your business needs.

What is the production capacity of a hard candy production line?

A candy production line’s production capacity refers to the maximum amount of candy that can be produced within a given period. This is affected by several factors such as the type of candy being produced, the rate of ingredients and materials consumption, the speed of the machinery, the skill level of the workers, and the time needed for quality control checks. The production capacity of a candy production line can be determined by calculating the time required to produce a batch of candy and the number of batches that can be produced in a day. Through this, candy manufacturers can streamline their production process to meet the market demand and increase efficiency.

The role of a packaging machine in managing production capacity

A packaging machine plays a significant role in managing the production capacity of a candy production line. After the candy is manufactured, it needs to be packaged efficiently to increase its shelf life, prevent contamination, and make it easy for transportation. The packaging machine automates the process of packaging the various candy types in the required quantities and specifications. This increases the productive output of the candy production line while ensuring that the manufacturer meets their customer's demands promptly. This process also assists with regulating the number of bags produced and reduces the amount of wasted packaging materials.

Exploring the different types of candies produced on a production line

A candy production line can produce a wide range of candies. These can range from hard candies, lollipops, caramels, and soft and hard chews to chocolates. Each of these types of sweets requires a different production process specific to the desired results. For example, hard candies need a prolonged boiling to achieve the desired texture while chocolates require tempering and molding. A wide variety of candy types accommodates different preferences and changes in the market demand, ensuring that the candy manufacturer can respond to other customer needs quickly.

The significance of a candy maker in the manufacturing process

A candy maker plays a vital role in the candy manufacturing process. Their skills and experience are critical in creating quality and safe candy products. A candy maker must have a deep understanding of the candy making process, follow the recipes accurately, carry out quality checks, and troubleshoot any issues that may arise during the production process. They oversee the process of adding ingredients, cooking, and creating different shapes and designs of the candies. The candy maker’s skills and experience significantly impact the quality of the final product.

Die-formed hard candies and their place on a candy production line

Die-formed hard candies are candies with distinct shapes and designs achieved through molds. These molds are placed in the production line after the boiling process, and the candy mixture is poured in, creating the desired shape of the hard candy. Die-formed hard candies are a popular choice for marketing since they can be made in any form, even designs that match a company logo or holiday-themed designs. Their production process is vital and requires strict quality control measures to achieve the desired shapes, sizes, and colors. Die-formed hard candies can significantly boost a candy manufacturer's output and revenue.