Over 30 Years Production Experience

Provide You with Lollipop Production Line Solutions

Trustworthy China Candy Machine Manufacturer

Most Popular Lollipop Production Line Series

Medium Scale Lollipop Production Line

L-80

Medium Scale Lollipop Production Line

L-150

Large Scale Lollipop Production Line

L-300

Large Scale Lollipop Production Line

L-600

Ultra Large Lollipop Production Line

L-1500

Related Products

Candy / Gummy Kitchen CIP Cleaning System

Steam-Humidifying & Sugar-Sanding Machine

Automatic Weighing & CFA Adding Station

Raising Film Continuous Cooker

Specification Sheet for a Standard Lollipop Production Line

| Model | Capicity(kg/h) | Casting Particles(hr) | Power(kw) |

| L-50 | 50 | 15,000 | 20 |

| L-80 | 80 | 25,000 | 20 |

| L-150 | 150 | 40,000 | 30 |

| L-300 | 300 | 80,000 | 35 |

| L-450 | 450 | 120,000 | 40 |

| L-600 | 600 | 240,000 | 45 |

| L-1500 | 1500 | 800,000 | 50 |

| Stage | Parameter | Range |

| Raw Material Handling | Raw Materials | Sugar, glucose syrup, flavorings, colors |

| Material Compatibility | Various types of sugar and ingredients | |

| Cooking and Mixing | Cooking Temperature | 150°C - 170°C |

| Mixing Time | 15 min - 30 min | |

| Molding and Forming | Molding Shape | Round, heart-shaped, etc. |

| Molding Temperature | 50°C - 60°C | |

| Insertion of Sticks | Stick Size | 100 mm - 150 mm |

| Insertion Speed | 50 sticks/min - 100 sticks/min | |

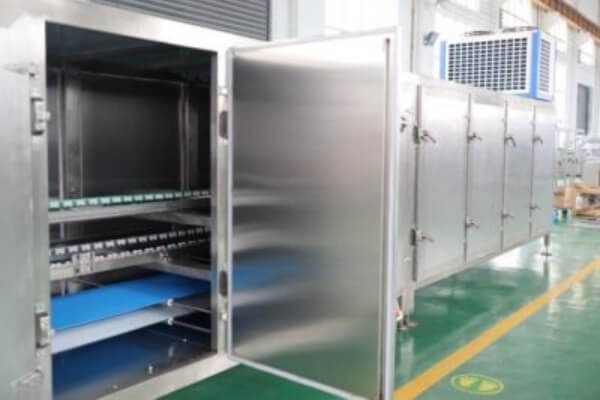

| Cooling and Solidification | Cooling Tunnel Length | 10 m - 20 m |

| Cooling Temperature | 20°C - 25°C | |

| Shaping and Cutting | Cutting Shape | Round, star-shaped, etc. |

| Cutting Speed | 100 cuts/min - 200 cuts/min | |

| Sugar Coating | Sugar Layer Thickness | 1 mm - 3 mm |

| Coating Drum Speed | 20 RPM - 40 RPM | |

| Flavor and Color Application | Application Rate | Adjust based on specifications |

| Inspection and QC | Vision Inspection System | Detecting defects |

| Reject System | Automatically remove faulty lollipops | |

| Packaging | Packaging Type | Wrappers, blister packs, etc. |

| Packaging Speed | 30 packs/min - 60 packs/min | |

| Energy Consumption | Energy Consumption | 50 kW - 100 kW |

| Safety Measures | Emergency Stop Buttons | Yes |

| Guarding | Yes | |

| Maintenance Schedule | Cleaning Frequency | Daily, after each batch |

| Lubrication Points | Every 40 - 80 hours |

Advantages of Junyu Lollipop Machine

The Junyu Lollipop Machine offers unparalleled versatility in confectionery production, allowing for a vast array of hard candy lollipops. You can create multi-color and multi-component candies with ease, whether you're looking for one, two, three, or four colors.

Partner with us to produce unique, high-quality confectionery and nutraceuticals and achieve a high, long-term return on your investment.

Lollipop Production Line Core Components and Systems

1. Kitchen System

A: Continuous microfilm cooker for hard candy syrup

- More transparency and smoothness

- Less affected by room temperature

- Lower reducing sugar and less combustion color

- Less moisture and longer storage shell life

- Less cooking time and better crystal appearance

- A precise temperature control system preserves the activity of additives.

B: Microfilm cooking system

The dissolved syrup in the buffer tank will be fed by rotor pump, through flow meter and filter, it enters the bottom of the tubular cooker, it will be heated to the setting temperature equally, then send to vacuum chamber for getting the required brix.

- There isn’t any wearing part and metal piece, easy to maintain.

- It is easy to disassemble and clean, no dead spots

- Stable cooking temperature and heat more evenly.

- Vertical and compact design for space-saving installation.

- Short reaction time and gentle treatment of product in process.

- Minimizes thermal radiation, reduce heat consumption.

- With simple PID system

- SS304 frame

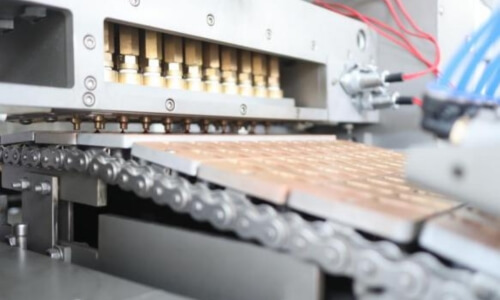

2. Automatically Depositing Line

The depositing machine can be regarded as the core executive component of the entire production line, and it directly determines the forming quality and appearance of lollipops. It is usually equipped with multiple depositing nozzles, and the number can be flexibly adjusted according to the mold specifications and production efficiency requirements. These depositing nozzles are carefully designed to enable the sugar liquid to be injected into the mold cavity at a uniform, stable flow rate and angle, ensuring that the sugar liquid is quickly and evenly distributed in the mold and avoiding defects such as bubbles and voids. Moreover, the height and angle of the depositing head can often be adjusted to adapt to molds of different thicknesses and shapes, greatly improving the versatility and flexibility of the equipment.

- New high-precision depositing with more accurate, less waste, higher yield

- Full stainless steel and waterproof sandblasting on surface

- Center filling, layer by layer, and double color twist functions

- Diversity of the mold types such as flat or 2D or 3D

- Flat(2D) & ball shape(3D) lollipop stick adding system

- Electrical parts with international brands for longer service life

- Warning signs of hidden parts and protection for safely using

- Double-layer insulation temperature holding system

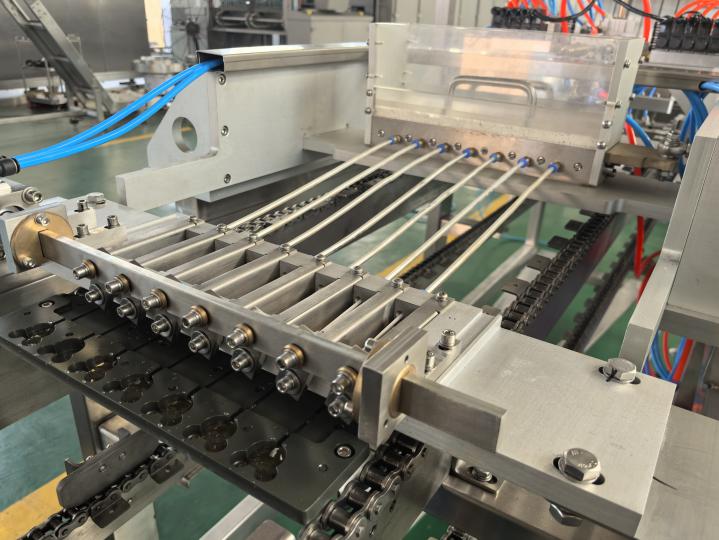

3. Automatic Stick Insertion Mechanism

Automatic stick insertion mechanism: Complete the lollipop stick insertion process

Composed of multiple independent pneumatic plug units, each corresponding to a mold hole position.

4. Mold Conveying Device

The mold conveying device is responsible for accurately transporting the mold to the bottom of the depositing head, and after depositing is completed, quickly moving it away to enter the subsequent cooling and demolding processes. This device generally adopts chain transmission or belt transmission, which operates stably and has an adjustable speed. During the conveying process, the mold is placed on a specially made tray or fixture to ensure that its position remains fixed, avoiding inaccurate depositing due to shaking or displacement. At the same time, the conveying device is also closely coordinated with the control system to realize synchronization with the action of the depositing head, ensuring the efficient and smooth operation of the entire production process.

5. Heating and Heat Preservation System

Since the fluidity of the sugar liquid is sensitive to temperature, a heating and heat preservation system is indispensable to ensure that the sugar liquid remains in a good liquid state during transportation and depositing. This system not only continuously heats and keeps the sugar liquid in the storage hopper within an appropriate temperature range but also heats the conveying pipes and depositing heads to prevent the sugar liquid from thickening or even solidifying due to temperature reduction during transportation. The heating method usually adopts electric heating or steam heating, and precise temperature control is achieved through temperature sensors and temperature control instruments to ensure minimal temperature fluctuation, providing a strong guarantee for a stable production process.

6. Cooling Tunnel

Cooling tunnel we use SUS304 stainless steel as the frame,thickened,stable operation,low noise, longer life cycle, we use better quality refrigeration equipment for better cooling effect. Our equipment and door handles have a very smooth surface, beautiful appearance, strong and sturdy, and are easy to clean.

About Junyu

Top Lollipop Candy Making Machine Manufacturer in China

Shanghai Junyu Food Machine Co., Ltd., founded in 1987, is a leading innovator in confectionery machinery, rooted in over three decades of expertise that began with our founder’s pioneering candy machines in the early 1980s.

Based in Shanghai Fengxian Industrial Zone, we design and manufacture world-class candy production lines, delivering tailored solutions to clients in over 100 countries. We are the ideal partner for food companies, raw material suppliers and agents.

Why Choose Us

Types of Lollipops We Produce

FAQs

Choose the Best China Candy Machine Production Equipment

Junyu is a company dedicated to creating machines that are customized case by case and every lollipop machine created is tailor-made to your specific needs.

The Complete Guide to Lollipop Production Line

Are you interested in starting your own lollipop production line? Look no further! Junyu is here to provide you with a complete guide to lollipop production. Our comprehensive and informative guide covers everything you need to know, from the ingredients and equipment required to the step-by-step process of creating mouth-watering lollipops. Whether you’re a beginner or an experienced confectioner, our guide is designed to help you master the art of lollipop production. Don’t miss out on this exclusive offer, and start your journey towards becoming a lollipop manufacturing expert today!

1. What is a lollipop production line?

A lollipop production line refers to machinery and equipment used to manufacture lollipops from raw materials to the finished product. It is a complex process that requires precise temperature control, continuous stirring, shaping, cooling, and wrapping. The production line is critical in determining lollipops' final quality, design, and texture.

Understanding the Production Process

The lollipop production process involves three main stages: mixing and cooking, shaping, and cooling and wrapping. Raw materials such as sugar, glucose, and water are combined in a mixer and then poured into a lollipop machine for shaping. The shaped lollipops are cooled and wrapped using high-quality packaging materials, ready for distribution and sale.

The Role of a Lollipop Making Machine

A lollipop making machine is a critical piece of equipment in the production line. The engine determines the lollipop's size, shape, and design and can also control the temperature and speed of the production process. Manufacturers can efficiently produce large quantities of high-quality lollipops with consistent quality and flavors with a lollipop machine.

The Benefits of an Automatic Lollipop Production Line

An automatic lollipop production line offers several advantages to manufacturers. It speeds up the production process, reduces labor costs, and ensures consistency in quality and flavor. The machines are also easy to operate and maintain and can be customized to meet different production needs and requirements.

Choosing the Right Machine Manufacturer

Choosing the proper machine manufacturer ensures the production line's success. Manufacturers should consider factors such as the company's reputation, experience, and expertise in producing lollipop making machines. They should also evaluate the machine's features, capabilities, and production capacity to meet their needs and requirements.

Factors to Consider When Buying a Lollipop Machine

Manufacturers should consider factors such as production capacity, size, design, automation level, and maintenance requirements when purchasing a lollipop machine. They should also examine the machine's overall build quality, durability, and safety features to ensure it meets the highest industry standards. Additionally, they should compare prices and warranties from various manufacturers to make an informed decision.

2. Types of lollipop production lines

Lollipop production lines are a must-have for those in the confectionery industry. These machines make it possible to produce lollipops in large quantities with enhanced accuracy and precision. The market has two main types of lollipop production lines: automatic and semi-automatic. Automatic lollipop making engines tend to be more expensive, but they have higher production capacities and require less manual labor than semi-automatic machines.

Differentiating Between Lollipop and Candy Production Lines

Lollipop and candy production lines have one thing in common: they churn out sweet treats. However, candy production lines generally produce a broad range of sweets, which doesn't limit them to only lollipops. On the other hand, lollipop production lines are specifically designed to create lollipops, making them ideal for those looking to focus on building this particular type of sweet treat.

The Features of a Lollipop Candy Making Machine

Lollipop making machines feature different stations where the production process takes place. They have a depot and cooker station where the lollipop ingredients are melted and mixed to form syrup. Once the syrup is ready, it is cooled on a cooling plate, and then it goes to the forming machine, where lollipop sticks are inserted, and the lollipops are shaped before they are transferred to the wrapping machine, where they are wrapped and packaged.

Exploring Options for Depositing Machines

Depositing machines are an essential feature in lollipop production lines. They deposit the lollipop syrup onto the sticks gently pulled out of the forming machine. The machines come in different types, such as the piston depositor and the gear pump depositor. Although their functions are similar, they differ in terms of the kind of lollipop production lines they can work on and the types of lollipops they produce.

Understanding Production Capacity

The production capacity of a lollipop production line refers to the number of lollipops that can be produced within a given period. The capacity of a lollipop machine is determined by factors such as the speed of the production line, the size and complexity of the device, and the type of lollipop produced. The production capacity of a lollipop machine can range from a few hundred lollipops per hour to several thousand lollipops per hour.

Comparing Fully Automatic and Semi-Automatic Machines

Fully automatic lollipop machines are designed to operate with minimal manual intervention and have high production capacities compared to semi-automatic machines. On the other hand, Semi-automatic machines are designed for smaller production capacities and require more operator intervention. Fully automatic machines are more expensive than semi-automatic machines, but they offer greater efficiency, excellent accuracy, and faster production rates. Ultimately, the choice between fully automatic and semi-automatic lollipop machines depends on the volume of production needed and the available budget.

3. Key considerations before starting your production

Types of Lollipops and Their Requirements

There are several types of lollipops, each with its unique characteristics. Common types include hard candy, soft candy, filled, layered, and novelty lollipops. To ensure the success of your lollipop production, you must understand the specific requirements for each type, such as ingredients, flavors, colors, sizes, and textures. For instance, hard candy lollipops require precise temperature control during cooking, while filled and layered lollipops need specialized molds and equipment for loading and layering.

The Importance of Lollipop Sticks

Lollipop sticks are a crucial component of lollipop production and play a significant role in the final product's quality. The sticks provide the structure for the candy, and choosing the suitable stick material can impact the lollipop's appearance, texture, and overall appeal. Common stick materials include plastic, wood, and paper, each with advantages and disadvantages. Plastic sticks are durable and easy to use but not eco-friendly. Wood sticks are environmentally friendly but can break or splinter, while paper sticks are biodegradable but can become soggy or weak. Consider the type of candy you are producing, the packaging, and your target customer when choosing the stick material.

Ensuring the Quality of Your Lollipop Products

Quality is critical in lollipop production, and it is essential to use high-quality ingredients to ensure a consistent, delicious taste and appealing appearance. Establishing a detailed quality control plan that includes inspection points throughout the production process can help maintain product consistency, avoid recalls, and retain customer loyalty. Adherence to health and safety regulations is crucial to preventing contamination, spoilage, and other hazards. Regularly train your staff, maintain cleanliness, monitor equipment, and conduct internal audits to ensure your products meet the highest quality standards.

Choosing the Right Machine Production Line

Choosing the right machine production line can significantly impact your lollipop production's efficiency and profitability. Machine production lines come in different sizes, features, and degrees of automation to cater to diverse production requirements. When selecting a production line, consider factors such as the size of your production facility, the types of lollipops you produce, the budget, and the desired level of automation. A reliable and efficient machine production line can help you save time, reduce costs, and deliver consistent, high-quality lollipops at scale.

Implementing a Reliable Hard Candy Production Line

Hard candy lollipops can be challenging due to their precise temperature control requirements. A reliable hard candy production line can help you overcome these challenges and streamline your production process. A hard candy production line comprises specialized equipment such as mixers, cookers, and cooling tunnels, which can help ensure that your hard candy lollipops meet the highest quality standards. Automation and modern control systems can also help you reduce production time and costs while improving consistency and quality.

4. The Lollipop Production Process: From Raw Materials to Finished Lollipops

Lollipop production involves several stages: sugar boiling, molding, shaping, and packaging. The process starts with dissolving granulated sugar in water and boiling it until the syrup reaches a specific temperature and consistency. The syrup is then mixed with flavorings, colors, and stabilizers before being poured into molds to solidify. The lollipops are then removed from the molds, coated with a candy shell, and wrapped in clear cellophane to create the finished product.

Step-by-Step Guide to Operating a Lollipop Making Machine

Operating a lollipop-making machine requires attention to detail and precision to ensure consistent output and quality. First, set up the device according to the manufacturer's instructions and make sure all parts are clean and debris-free. Then, select the appropriate settings for the type of lollipop being produced, such as flavor, color, and size. Once the settings are configured, start the machine and monitor the output to ensure that each lollipop is appropriately formed and shaped. Keep the device well-maintained and follow regular cleaning procedures to prevent contamination and guarantee hygiene.

Optimizing the Production Line for Efficient Output

Efficient lollipop production requires optimizing the entire production line, from raw materials to finished products. This involves identifying points where bottlenecks occur and making adjustments to reduce waste, increase productivity, and improve profitability. One way to optimize production is by improving the efficiency of the mixing and pouring process to minimize the time between stages. Regularly monitoring production metrics, such as throughput and yield, can also help identify areas for improvement.

Ensuring Hygiene and Safety in the Production Process

Keeping the production line clean and safe is crucial for producing high-quality lollipops. This involves following standard hygiene practices, such as wearing gloves and other protective gear, properly storing raw materials, and regularly cleaning and sanitizing all equipment and surfaces. Additionally, implementing a Hazard Analysis and Critical Control Points (HACCP) program can help identify potential hazards and develop preventative measures to ensure the overall safety of the production process.

Common Challenges and Troubleshooting in Lollipop Manufacturing

Lollipop production can present various ingredients, processing, and equipment challenges. For example, the wrong proportions of sugar, water, or flavorings can affect the texture and taste of the lollipops. Issues with the candy shell can also occur, such as cracking or not adhering correctly to the surface of the lollipop. Troubleshooting these challenges often involves isolating the source of the problem, adjusting variables in the production process, and ensuring that equipment is well-maintained and calibrated.

5. Expanding your lollipop production

If you're running a lollipop production business, you're probably constantly looking for ways to innovate and scale up your production. This article will provide practical advice and insights on expanding your lollipop production, venturing into new product ranges, such as gummy candies and hard candies, and collaborating with suppliers and distributors.

Introducing New Flavors and Designs: Keeping Up With Emerging Trends

Developing new flavors and designs is crucial to stay relevant in the confectionery market. Start by conducting market research to identify emerging trends and experiment with different flavor combinations to create unique offerings that stand out. Don't be afraid to get creative with packaging and designs, and consider offering personalized or custom-made lollipops to attract niche markets.

Scaling Up Production Capacity: Boosting Efficiency and Reducing Wastage

As your business grows, you must increase production capacity while maintaining quality standards. Monitor your production efficiency and optimize processes to reduce wastage, such as using automated machinery and ordering ingredients in bulk. Consider outsourcing specific tasks, such as labeling or packaging, to free up your time and resources.

Exploring Opportunities for Gummy Candy Production: Venturing Into a New Product Range

Expanding your product range to include gummy candies can open up new markets and revenue streams for your business. Before diving into production, do your research on the different types of gummy candies, such as traditional, sour, or sugar-free, and experiment with different flavors and shapes. Remember to factor in additional equipment and production costs when considering this expansion.

Expanding Your Product Range With Hard Candy: A Sweet Addition

Hard candies are another potential product range to expand your business. Again, conduct market research to identify popular flavors and shapes and experiment with unique combinations. Hard candies can be made using a mixture of sugar, corn syrup, and flavorings, with the option to add color and designs.

Collaborating With Suppliers and Distributors: Building a Strong Network

Building a network of reliable suppliers and distributors is crucial for expanding your business. Establish partnerships with local or regional suppliers to ensure a steady supply of quality ingredients, and consider outsourcing distribution to reach new markets. Network with other confectionery businesses to exchange ideas and partnerships to drive growth. In conclusion, expanding a lollipop production business requires innovation, increased efficiency, and strategic partnerships. Implementing the insights in this article can help you grow your business to new markets and strengthen your position in the confectionery industry.