Over 30 Years Production Experience

Provide You with Marshmallow Production Line Solutions

Trustworthy China Candy Machine Manufacturer

Marshmallow Production Line

Our complete, fully automated continuous production line creates premium marshmallows in various colors, shapes, and filled varieties.

- Premium Texture: Produces highly aerated, smooth, and fluffy marshmallows.

- Shape & Color Variety: Extrudes up to 4 colors and multiple shapes, including twisted ropes.

- Creative Fillings: Deposits center-filled and dual-color marshmallows, ideal for ice cream-style treats.

- Fully Automated: Integrated drying system eliminates manual handling until packaging.

- Complete Solution: Covers the full process from boiling to drying and packaging.

- Maximum Customization: Supports single/multi-color, twisted, cartoon, ice cream, and fruit-filled designs.

Full Automatic Marshmallow Production Line Series

Medium Scale Marshmallow Production Line

JYM-600

Medium Scale Marshmallow Production Line

JYM-900

Large Scale Marshmallow Production Line

JYM-1200

Specification Sheet for a Standard Marshmallow Production Line

| Model | Working Width | Capacity | Product Color | Extruder Nozzles | Depositing Nozzles |

| JYM-500 | 450mm | 80-150kg/h | Sing Only | Max 5 | No |

| JYM-600 | 600mm | 120-200kg/h | 4 Colors | 5-6 | 12+ |

| JYM-900 | 900mm | 200-300kg/h | 4 Colors | 8-12 | 24-28 |

| JYM-1200 | 1200mm | 300-500kg/h | 4 Colors | 16 | 36-45 |

Discover Our Marshmallow Production Line

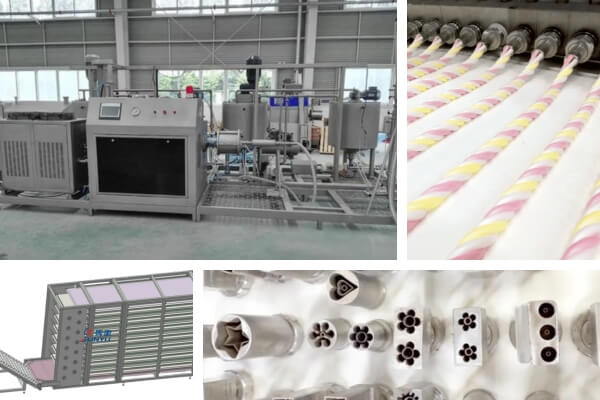

Marshmallow Extruder

The extruder forces a precise marshmallow mix through nozzle tubes, creating continuous ropes up to 20 m long. After ageing and cooling, a servo cutter slices them into uniform pieces.

Each nozzle head can run four separate ropes at once, with up to four colors or a filled center in each strand. An optional sugar‑crisp shell coater adds a delicate, crunchy exterior.

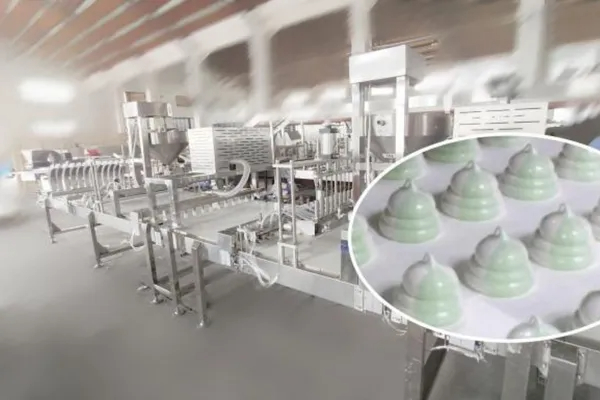

Marshmallow Depositor

This starch‑based mogul depositor accurately fills molds—balls, ice‑cream shapes, 3D fruits—and handles up to four colors or components in one deposit, including soft center fills. The result: perfectly shaped, multi‑colored marshmallows every cycle.

Marshmallw Machine Extruder Nozzles

The extruder nozzles are custom‑designed—from sampling and drawings to precision fabrication—by a 30‑year extrusion expert, matching any color or shape trend.

Bespoke nozzles and molds let you produce unique multi‑cavity, 3D, or center‑filled marshmallows at scale, setting your line apart.

Marshmallow Aerating System

Warm, gelatin‑rich syrup is fed through a three‑zone aerator head—kept just above gelatin’s melting point by hot and cold water chillers—while compressed air is injected. In the rotor‑stator chamber, rotating and stationary pins shear the air into micro‑bubbles, producing a continuous stream of light, fluffy marshmallow ready for forming.

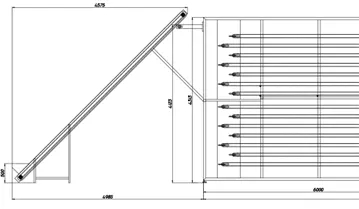

Marshmallow Starch Mogul System

Our automated continuous dryer gently removes moisture from gelatin‑based marshmallows in adjustable 3–24 hour cycles, with an integrated bacteriostatic module to inhibit microbes. A low‑temperature dehumidifier maintains precise humidity control, yielding perfectly chewy confections with extended freshness.

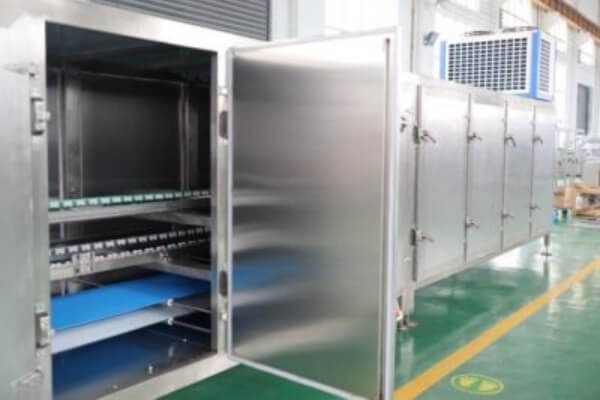

Marshmllow Drying System

Our fully automatic continuous dryer removes moisture in adjustable 3–24 hour cycles with a built‑in bacteriostatic module. A low‑temperature dehumidifier maintains precise humidity, delivering consistently chewy marshmallows with extended freshness.

About Junyu

Top Marshmallow Making Machine Manufacturer in China

Shanghai Junyu Food Machine Co., Ltd., founded in 1987, is a leading innovator in confectionery machinery, rooted in over three decades of expertise that began with our founder’s pioneering candy machines in the early 1980s.

Based in Shanghai Fengxian Industrial Zone, we design and manufacture world-class candy production lines, delivering tailored solutions to clients in over 100 countries. We are the ideal partner for food companies, raw material suppliers and agents.

Why Choose Us

Types of Marshmallows We Produce