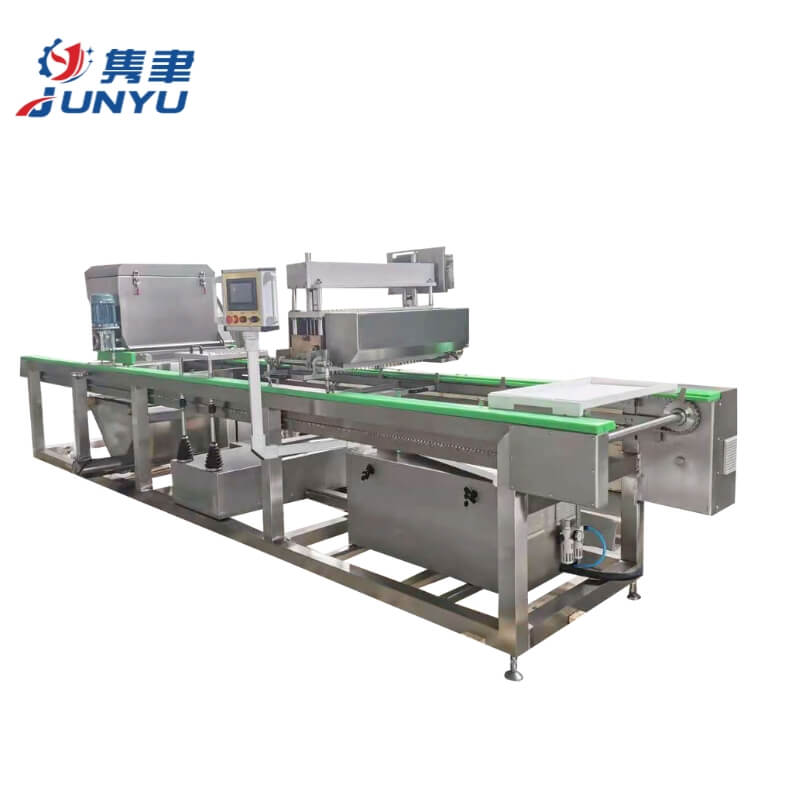

Semi-Automatic Model Starch Mogul Line

Description

Reviews

Semi-Automatic Candy Machine | 80–800 kg/h Capacity

A space-saving solution for high-quality gummy and jelly production.

Ideal for small-to-medium factories seeking efficiency without full automation, our semi-automatic starch mogul line blends traditional candy craftsmanship with modern upgrades.

Key Features at a Glance

- Production Capacity: 80–800 kg/h

- Energy Saving: 40% lower power consumption vs. full-auto lines

- Dust Control: Integrated vacuum system reduces dust by 90%

- Starch Recycling: 15% faster than gravity-fed systems

- Mold Flexibility: Quick-change molds (hearts, animals, etc.)

- Global Use: Voltage range 110–440V

Gummy Depositing Machine Models

| Model | Tray Size (cm) | Candy Qty/Stroke | Depositing Speed (times/min) |

| JYS-150 | 40×40 | 64–180 pcs | 15–20 |

| JYJ-300 | 40×60 | 200–300 pcs | 15–20 |

| JYJ-600 | 40×80 | 528–720 pcs | 15–20 |

Custom tray sizes: 400×400 / 300×600 / 400×600 / 400×800 mm available.

Core Machine Layout

1. Cooking Unit

Electric or steam jacketed kettle with PLC control for ±1°C accuracy. Ensures perfect dissolution of sugar, glucose, and water.

2. Semi-Automatic Mogul

Servo-driven tray conveyor with 18–22 deposits/minute. Supports single/double color, layered, and center-filled candy designs.

3. Starch Conditioning & Recycling

Integrated vibrating sieve and air-return system recycles 85% of starch, significantly reducing raw material usage.

4. Curing & Drying Room

Trays remain in a temperature-controlled room for 2–4 hours—no additional conveyors required.

5. De-starching & Oiling / Sugar Sanding

Manual discharge station with dust hood. Optional oil or sugar coating unit for glossy or matte finishes.

Advanced Features

Revolutionary Dust-Free System

- 90% reduction in airborne dust (ISO 14644-1)

- 35% smaller footprint than traditional dusting units

- OSHA/CE-compliant PM2.5 containment

- Cuts cleaning labor costs

Semi Candy Depositor

- Time-saving alternative to manual operations

- Handles small to mid-sized batches with precision

- Easily adapts to new candy recipes as product lines grow

Optional Upgrades

Automatic Candy Cooking System

For scaling up production with fully automated sugar melting and mixing—ideal for consistent, high-volume output.

Candy Mold Printer

Create custom molds in hours. Upload your design and print food-safe molds in-house—perfect for seasonal, branded, or signature candy shapes.

Sugar Sanding Machine

Gives your candy that perfect sugary finish. Suitable for:

- Sugar-coated gummies & jellies

- Chocolate-dragée nuts (almond, peanut, cashew)

- Pharmaceutical tablets

- Flavored or spiced seeds and nuts

Specifications:

- Capacity: 25–3,600 kg/h (batch or continuous)

- Heating: Electric, gas, steam, or hot air

- Controls: PLC with touch screen, variable speeds, steam jets

- Cleaning: Quick-release drum, easy-to-swing sugar hopper

Common Machine Types

| Type | Description |

| Rotary/Pan Coater | Classic drum type; batch or continuous |

| Mini/Lab Coater | Tabletop, for R&D or pilot runs (2–40 kg/batch) |

| Continuous Coater | Inline system for large-scale sanding |

Need help customizing your production line?

Our team of confectionery specialists is ready to support you with tailored machine setups and flexible automation levels.